Features

This machine is a kind of high-and new-tech product integrating light, machinery and electricity with pneumatic which can be used for both thick and thin paper, realizes whole-course automstion and adopts belt conveying with high speed and high efficiency. The mechanical speed adopts variable frequency step less speed regulation and max. Speed is 60 m/min. This machine has independent space for every working station and it can be assemble bases the client request,so it is suitable for being used in large printing enterprise.

1.Stream Feeder

-Suctior head with vacuum pump suction system requires no lubricant of oil.

-The feeder can be adjusted while running.

-Double sheet detector

2.Sheet Cleaning Unh

-press the paper even.

-Remove the remaining dust after printing,

-dusting function, add to the evenness and smoothness after the paper is glazed.

3.Base Coating Unit

-Smear the foundation oil, to fill up the capiliary function of the paper surface.

-Add the adhesiveness force between UV layer and the oily ink.

-Reduce the penetration of UV coatings,to keep the paper white.

-Saves the precious UV oil consumption.

4.I.r. Drying Conveyor

-Infrared drying equipment.

-Cooling fan system,

-Fit for drying job after the smearing of water or soluble.

5.UV Coating Unit

-UV coating unit, equipped with high sensitivity wind-knife system,suitable for glazing of thick and thin paper.

-Mioro-adjustment for even smearing and control of material usage, makes the paper smooth and glossy.

6.UV Drying Unit

-UV radiation makes the UV oil harden and become resistant to wear, and promote the glossiness of the paper surface.

-Equipment with fast cooling equipment,avods paper curling,

7.Automatic Delivery Unit

-Conveyor belt pfoduces low noise and make delivery smooth with its upper and lower pressing track design. Smearing on thin paper tends to produce curling,yet the peneumatic sheet jogging device knocking up both sides of sheet and keep the paper stable.

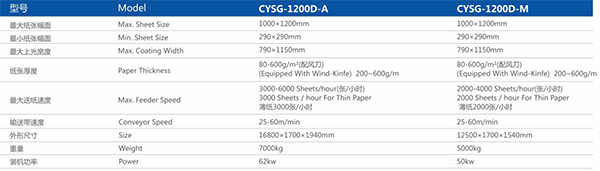

Main Technical Variables

Home >> CYSG-1200D Automatic Uv Coating Machine( Three Coaters)

Home >> CYSG-1200D Automatic Uv Coating Machine( Three Coaters)